Need a solution? Let’s start the conversation

About TechSolutions

With headquarters in Shanghai, China, TechSolutions is providing engineering, procurement, modular fabrication, construction management and operation & maintenance services for years.

We’ve developed extensive expert know-how in designing, procurement and fabrication, construction and installation, commissioning, operation and maintenance of all kind of bulk materials handling system or machine with over years. From continuous opencast mining systems, in-pit crushing and conveying system to stacking, reclaiming, blending, conveying, train/truck loading & unloading facilities, overland transport, stockyards, terminals/ports ship loading & unloading facilities, we offer cost-efficient, environmentally friendly integrated solutions from individual machines, turnkey projects to EPC projects to the clients in mining, metallurgical facilities, steel mill, coal-fired power plant, cement, chemical, fertilizer industries.

After years of operation, TechSolutions has developed from an engineering company specializing in bulk material handling initially to a one-stop integrated solutions provider for projects in aluminum industry chain, mining, metal, power, oil & gas, ports & terminals, we are able to provide project full life cycle services from project development, financing, engineering consulting (project proposal, feasibility study, market investigation, etc.), engineering design, procurement, construction, commissioning, performance test, operation and maintenance, upgrading and reconstruction for the clients worldwide.

At present, our core business are:

• Bulk Material Handling and Mineral Processing

• Aluminum Industry Chain Projects ( bauxite → alumina refinery → aluminum smelting & processing )

• Mining & Metal Projects

• Power Projects

• Oil & Gas Projects

• Services and Trade

TechSolutions has the ability to undertake project contracting (EPC, EPC+F, EP+S, EPC+O&M, PMC, etc.) for bauxite mining, alumina refinery plant, aluminium smelting plant, aluminum processing plant, copper mining/smelting/processing plant, coal/gas fired power plant, wind farms, solar power plant, biomass power plant, oil & gas transmission & storage, port infrastructure and related industries projects worldwide.

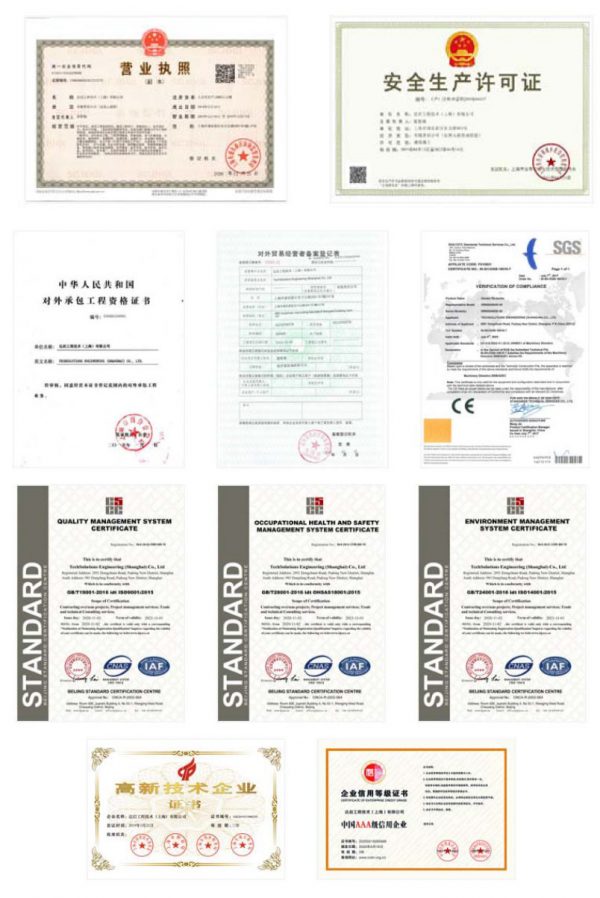

Qualification Certificates

TechSolutions has passed many international system certifications, including ISO9001 quality management system certification, OHSAS18001 occupational health and safety management system certification, ISO14001 environmental management system certification, EU EN1090 certification, etc. The company was awarded top credit (AAA) enterprise and high-tech enterprise in China.

Engineering Design Capabilities

TechSolutions’s engineers are some of the most experienced experts in their respective fields of expertise. They work together every day to develop comprehensive solutions to meet client objectives. These teams comprise engineers who have worked on multiple projects in diverse industries.

TechSolutions conceptual and basic design capabilities align each project’s function, scope, cost and schedule with client objectives to optimize project success. Our conceptual design phase offers the best opportunity to assess business, commercial and technical risks; and to improve our clients’ return on investment.

The detailed engineering and design phase is a key step delivering capital projects. We develop plans to ensure that the designs reflect client requirements and facilitate construction of facilities meeting our clients’ strategic objectives.

TechSolutions multi-disciplinary engineering team specializes in bulk material handling, aluminum, power and mining, oil & gas for nearly 20 years, holds required knowledge and best practices, which allow us to provide tailored engineering design, products and services solution with cost advantage in the whole project life cycle.

Our engineering design services go through the earliest stages of concept planning, feasibility study, basic design, detail design, procurement & fabrication, construction, commissioning, until operation & maintenance.

Our Engineering design disciplines across all disciplines including process, mechanical, piping, civil, structural, electrical, controls, instruments, HVAC, etc. We develop, implement and apply the design work specific to the needs of each project, fully compliant with international standards.

With the simulation, interactive 3D simulation modeling, finite element analysis, discreet element method (DEM) and other BIM tools, we can bring our clients into the project before fabrication and construction begins; we conduct our engineering design work specific to the needs of each client’s project.

We have standardized some parts of bulk material handling equipment to shorten design time, reduce possible errors in manufacturing and installation, improve product interchangeability to reduce delivery time, possible change cost during fabrication & construction and operating costs. We also considered maximizing pre-assembled module size and complexity in the design process to minimize on-site construction and erection effort.

Fabrication Facilities

TechSolutions operates self-perform fabrication yards and also uses independently operated yards to provide fit-for-purpose fabrication solutions for global clients’ capital projects. As part of TechSolutions integrated engineering, procurement, modular fabrication and construction offerings, our modular fabrication capability provide certainty of outcome.

TechSolutions modular fabrication base is located on the Southeast China Sea coast near Shanghai. TechSolutions modular manufacturing base has an advantageous geographical location, which can shorten shipping time to various markets around the world, and it is also convenient to get in touch with major cost-competitive suppliers and vendors in the region.

- Total Area: 540,000 m2

- Covered Area: 220,000 m2

- Assembly Area: 200,000 m2

- Storage Area: 118,000 m2

- Quaysides: 1,016 m

- Skidways (2): 280 m, 260 m

- Water depth: -10 m

TechSolutions modular fabrication base, with over 500,000 square meters, TechSolutions modular manufacturing base facilities are specifically designed for fabrication, pre-assembly and modular construction of bulk material handling equipment, port machine, conveyor system & components, steel structure module and pipe rack module facilities, including:

- 25 stackers reclaimer, 15 circular stockyard stacker reclaimer

- 40 ship loader, ship unloader, quayside container crane

- 15 car dumper, train loading stations, spreader, crushing station, etc.

- 1,000 various types of pulley

- 300,000 tons of module products (steel structure, modules, pipe rack module, pipelines)

- 200,000 tons of various steel structure

Modular Fabrication Base Facilities

TechSolutions modular manufacturing base facilities are specifically designed for fabrication, pre-assembly and modular construction of bulk material handling equipment, port machine, conveyor system & components, steel structure and modules, pipe rack modules facilities. The facilities at TechSolutions modularization fabrication base include:

- Steel Cutting Workshop

- Structure Welding Workshop

- Blasting & Painting Workshop

- Piping & Outfitting Workshop

- Warehouse

- Assembly workshop

- Pre-assembly Yard

- 8,000T Skidway

- 12,000T Skidway

- Maintenance & Repair

- #1 Quayside

- #2 Quayside

- Utilities

- Offices