Do You Have Twin Boom Stacker Project We Can Help With?

Twin Boom Stacker

Stacker is used to stack bulk materials transported by belt conveyor system to the stockyard. Bulk Materials transported by belt conveyor system are stacked to the stockyard through tripper car, chute and hopper, boom belt conveyor. Stacker is an efficient machine for continuously stacking of bulk materials with particle size less than 300mm in storage yards of thermal power plants, ports and terminals, steel plants, coking plants, mines, alumina refinery plants and other industries.

If you’re looking for a reliable and efficient dual boom stacker, then you might want to consider TechSolutions.

At TechSolutions, we specialize in providing top-quality design, modular fabrication, installation, and commissioning services for twin boom stackers. Our team of experts has years of experience in the field of bulk material handling, and we are committed to delivering high-quality solutions that meet your specific needs.

Our twin boom stackers are designed to handle a wide range of materials, including coal, limestone, iron ore, and other bulk materials. They are equipped with state-of-the-art technology that ensures maximum efficiency, accuracy, and reliability in handling materials.

What is A Dual Boom Stacker?

Dual boom stacker is a type of bulk material handling equipment that is used to stack bulk materials such as coal, iron ore, limestone, and other materials in large stockyards. It is a versatile machine that can handle a wide range of materials, and is commonly used in industries such as mining, power generation, and cement production.

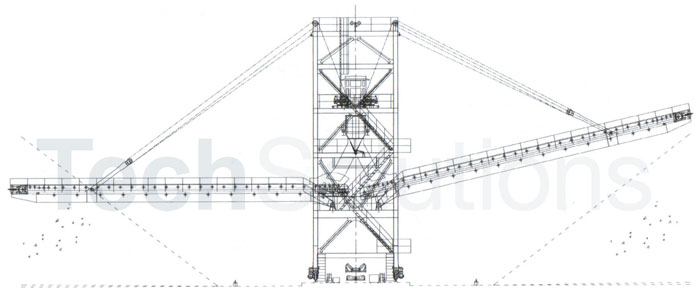

Dual boom stacker consists of two booms mounted on a tower structure platform, which allows the machine to cover a wide area and stack materials in multiple rows. The booms are equipped with a conveyor belt system that can move horizontally and vertically, allowing the machine to stack materials at various heights and positions.

The twin boom stacker is typically used in conjunction with a reclaimer, which is another type of material handling equipment that is used to extract materials from the stockpile. The reclaimer typically operates in a complementary manner to the stacker, allowing the materials to be reclaimed and transported to other areas of the facility.

Twin boom stackers are an efficient and reliable solution for handling large volumes of bulk materials in industrial settings. They are designed to maximize efficiency and accuracy, while also being modular and easy to maintain, making them a popular choice for a wide range of applications.

How Does Twin Boom Stacker Works?

Twin boom stackers are designed to handle bulk materials such as coal, iron ore, limestone, and other materials in large stockyards. The machine consists of two booms mounted on a slewing deck, which allows the machine to cover a wide area and stack materials in multiple rows. Here is a general overview of how a twin boom stacker works:

- Approach to the stockpile: The twin boom stacker approaches the stockpile area where the bulk material is stored. The operator positions the machine to ensure that the booms are in the correct position to start the stacking process.

- Material pickup: The twin boom stacker uses its two booms to pick up the bulk material from the stockpile through twipper car and chute at the top of tripper car. The booms are equipped with conveyor belt systems that move horizontally and vertically, allowing the machine to stack materials at various heights and positions.

- Stacking: Once the material is picked up, the twin boom stacker starts the stacking process. The booms move the material to the desired location and stack it in multiple rows. The machine can stack materials in a variety of configurations, depending on the specific needs of the operation.

- Maintenance: Twin boom stackers require regular maintenance to ensure they are operating at peak efficiency. This includes routine inspections, lubrication of key components, and replacement of worn parts.

Dual boom stackers are designed to maximize efficiency and accuracy in the handling of bulk materials. They are a versatile and reliable solution for a wide range of industrial applications, from mining to power generation to cement production.

TechSolutions offer Twin Boom Stackers

As a leading provider of twin boom stacker, TechSolutions provide engineering design, modular fabrication, installation, and commissioning to worldwide clients, TechSolutions is proud to offer twin boom stackers apart from the competition.

TechSolutions designed dual boom stackers are used for light duty applications with capacities of up to 5,000 tons per hour. Dual boom stacker is able to luff the boom but without slewing function, dual boom stacker is designed to stack bulk material to the stockyards on two sides of the rails with chevron or cone stacking mode.

Similar to all TechSolutions designed bulk material handling equipment, the operation modes of dual boom stackers can be local control & operation, manual operation, manual remote control, semi-automatic unmanned operation and full-automatic smart unmanned operation.

Main Features of TechSolutions Dual Boom Stacker

Here are some of the key features of our twin boom stacker:

- Modular design: Our twin boom stackers are designed using modular construction methods, allowing for easy customization and flexibility to meet the specific needs of each client.

- High stacking capacity: Our twin boom stackers are capable of stacking materials up to 30 meters high, allowing for efficient use of space in large stockyards.

- Precise control: Our twin boom stackers are equipped with advanced control systems that provide precise control over the movement and positioning of the booms and conveyor system.

- High efficiency: Our twin boom stackers are designed to maximize efficiency and minimize downtime, with features such as automatic lubrication systems and easy access to key components for maintenance.

- Safety features: Our twin boom stackers are equipped with a range of safety features, such as emergency stop buttons, warning alarms, and safety lights, to ensure the safety of operators and personnel working in the stockyard.

- Customizable options: Our twin boom stackers can be customized with a range of options, such as dust suppression systems, weather protection, and remote monitoring systems, to meet the specific needs of each client.

At TechSolutions, we are committed to providing top-quality twin boom stacker solutions that meet the needs of our clients in the mining, power generation, and cement production industries, etc.

Key Components of Dual Boom Stacker

Twin boom stackers are large-size and long-term delivery bulk handling equipment that consist of several key components that work together to stack bulk materials. Here are some of the main components of a twin boom stacker:

- Long travel: Long travel mechanism is responsible for moving the entire machine horizontally along the stockyard or storage area to reach the desired location for stacking material. The long travel mechanism consists of a set of wheels or rails that are mounted on the machine’s base frame and a drive system that propels the machine forward and backward along the rails or wheels.

- Tower structure: Tower steel structures are the the frame that supports the entire machine. It is designed to withstand the weight of the stacker.

- Boom and conveyor system: The boom and conveyor system is the heart of the twin boom stacker. It consists of two booms that are mounted on a rotating platform and a conveyor belt system that moves horizontally and vertically. This system is used to pick up, move, and stack the bulk material.

- Drive system: The drive system is responsible for powering the machine and moving it around the stockyard. It typically consists of a diesel engine or an electric motor and a series of hydraulic pumps and motors.

- Control system: The control system is responsible for managing the various components of the twin boom stacker. It includes a series of sensors, controllers, and software that ensure the machine is operating efficiently and safely.

- Cabin: The cabin is where the operator sits and controls the machine. It is typically located at the top of the machine and provides a clear view of the stockyard.

- Supporting components: Twin boom stackers also include a variety of supporting components such as brakes, suspension systems, and safety features such as warning lights and alarms

Technical Data

| Item | Value |

|---|---|

| Stacking capacity | up to 5,000 t/h |

| Boom length | 15 – 40 m |

| Belt width | 600 – 2000 mm |

| Rail gauge | 6 – 20 m |

Clients Benefits

At TechSolutions, we understand that our clients have unique needs and requirements when it comes to bulk material handling. That’s why we are committed to providing top-quality twin boom stacker solutions that offer a range of benefits to our clients. Here are some of the key benefits our clients can expect when working with us:

- Increased efficiency: Our twin boom stackers are designed to maximize efficiency and minimize downtime, helping our clients to improve their overall production and reduce operating costs.

- Improved safety: Our twin boom stackers are equipped with a range of safety features that help to ensure the safety of operators and personnel working in the stockyard.

- Customized solutions: We work closely with our clients to design and fabricate twin boom stackers that meet their specific needs and requirements, ensuring they get a solution that is tailored to their unique circumstances.

- High quality: Our twin boom stackers are designed and fabricated using top-quality materials and components, ensuring they are built to last and can withstand the demands of heavy-duty industrial applications.

- Reduced environmental impact: Our twin boom stackers can be equipped with a range of environmental control systems, such as dust suppression systems, that help to reduce the environmental impact of bulk material handling operations.

- Expert support: We provide expert support throughout the entire process, from initial design and fabrication to installation and commissioning, ensuring our clients get a solution that meets their needs and is installed and maintained correctly.

- Increased profitability: By improving efficiency, reducing downtime, and minimizing operating costs, our twin boom stackers can help our clients to increase profitability and grow their business.

We are committed to providing top-quality twin boom stacker solutions that deliver real value to our clients.

Application

Twin boom stackers have a wide range of applications in the bulk material handling industry, including in mining, power generation, and cement production. Here are some of the key applications of twin boom stackers:

- Mining: Twin boom stackers are commonly used in the mining industry to stack and reclaim various types of minerals, ores, and other bulk materials. They are especially useful in open-pit mines, where large quantities of material need to be stacked and reclaimed quickly and efficiently.

- Power generation: Twin boom stackers are used in the power generation industry to stack and reclaim coal and other fuels used in power plants. They can be used in both coal-fired and biomass power plants, where large quantities of fuel need to be stored and managed efficiently.

- Cement production: Twin boom stackers are also used in the cement production industry to stack and reclaim raw materials, such as limestone, clay, and shale, as well as finished cement products. They are especially useful in large cement plants, where large quantities of material need to be managed efficiently.

- Port operations: Twin boom stackers are used in port operations to stack and reclaim bulk materials, such as coal, iron ore, and grain, in stockyards and terminals. They are especially useful in ports with limited space, where efficient use of space is critical.

- Steel production: Twin boom stackers are used in the steel production industry to stack and reclaim raw materials, such as iron ore and coal, as well as finished steel products. They are especially useful in large steel plants, where large quantities of material need to be managed efficiently.

At TechSolutions, we understand the diverse applications of twin boom stackers and can provide customized solutions to meet the specific needs of our clients in various industries.

Our Performance Experiences

TechSolutions have extensive experience designing, fabricating, installing, and commissioning stackers for clients in a wide range of industries. Our team of experienced engineers and technicians has a deep understanding of the unique requirements and challenges of the bulk material handling industry, and we work closely with our clients to provide customized solutions that meet their specific needs. By 2022, we have delivered 302 stackers and reclaimers to clients worldwide.

Over the years, we have completed numerous twin boom stacker projects for clients in the mining, power, cement production, port operations, and steel production industries. Our twin boom stackers have been proven to deliver high performance, reliability, and efficiency in even the most demanding industrial environments.

Contact Us

To learn more about our twin boom stacker solutions, please contact us today. You can reach us by:

Tel: +86 21 6890 6101

E-mail: service@techsolutions.com.cn

Alternatively, you can contact our sales team using contact form.

We look forward to hearing from you and helping you with your bulk material handling needs.

Technical Data

CAPACITY

up to 5,000 t/h

BOOM LENGTH

15 – 40 m

BELT WIDTH

600 – 2000 mm

RAIL GAUGE

6 – 20 m

Note: Above data can be adapted and may vary according to client’s requirement.