Bauxite Mining Process

Bauxite ores no matter gibbsite, böhmite or diaspore are the basic raw material for primary aluminum production. Böhmite and diaspore are both aluminium-oxide-hydroxides (AlO(OH)), while gibbsite is an aluminium hydroxide (Al(OH)3). The main difference between böhmite and diaspore is that diaspore has a different crystalline structure from böhmite. Differences in bauxite ore composition and presence of iron, silicon and titanium impurities influence their subsequent bauxite beneficiation (if required) and alumina refinery processing.

With the increases for high-quality aluminum products in industry and living, the demand for bauxite is increasing in the world; the first step in producing aluminium process is bauxite mining.

Overview

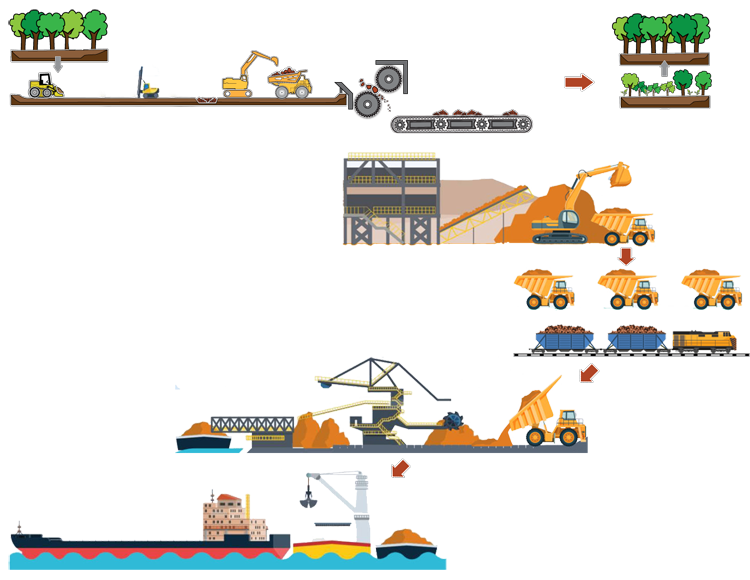

Bauxite deposits are normally found close to the surface in wet tropical and subtropical climates, so it is extracted mostly by open cast mining, but the bauxite mining processes may vary slightly depending on the location. But generally speaking, the bauxite mining process is roughly as follows:

- Before mining commence, the timber and vegetation on the land need to be cleared. Sometimes seeds and/or saplings may be collected in seedbank during this process for forming the basis of post-mining revegetation of the site.

- After this step the top soil will be removed and usually stored for replacement during rehabilitation. Sometimes there is a layer known as the “overburden” under the top soil, some surface bauxite mine deposits don’t have any overburden, and on others, the bauxite may be covered by rock and clayup to 20 meters. On average, the thickness of overburden is around 2 meters.

- The bauxite layer under the overburden is broken up by using blasting & drilling, then loaded by large excavators or surface miner into haul trucks, rail car wagons or belt conveyors then transported to bauxite beneficiation washing plant or to stockpiles, then shipped to alumina refinery plant.

Mining Steps

The mining process can be divided into below five steps:

- Clearing and Preparation

Pre-Mining Surveys will be conducted to provide information on mine sites to scope the mining area and plan mining activities. Then site undergoes clearing and preparation. Dense vegetation are removed to access the overburden or bauxite-rich layers. This process requires careful environmental management to minimize the impact on local ecosystems. - Bauxite Mining

Scrapers and small excavators are used to remove the remaining overburden and expose the caprock. Depending on the depth of the caprock, it can be broken by blasting, or simply removed with scrapers and excavators or surface miner. The bauxite is then mined using excavators or surface miner and loaders to load the bauxite onto haul trucks and transported to the crusher. Several pits are usually mined simultaneously in order to produce a consistent grade of ore. - Bauxite Crushing

Crushing station is used to break the bauxite ore down to a smaller size suitable for transport. The crushing station is made up of a number of components that include a vibrating screen, a crusher and sizers. Fine material drops through the vibrating screen while larger material passes over the screen to the crusher that breaks up the large rocks. The material that passes through the vibrating screen and jaw crusher is collected and passed through the sizer that further reduces the size of the material before it is transported via conveyor or ship to a refinery. The final size of the crushed bauxite ore is approximately 7.5cm or less in diameter. - Bauxite Transportation and Conveying

The crushed bauxite is transported by haul trucks, railway wagons or long-distance overland conveyors to alumina refinery plant or shipping port. - Bauxite Mine Rehabilitation

After mining, the edges of the pit are smoothed. Topsoil and overburden are returned to the site and the earth is prepared to prevent soil erosion and for seeding and planting. The logs and rocks that were put aside during clearing are then returned to provide shelter and nesting sites for animals.

What TechSolutions Offer

TechSolutions is a company that specializes in providing engineering design, procurement, construction (EPC) and operation services for bauxite mining projects, we has years of experience in the bauxite mining and has completed several bauxite mining projects in Guinea, Australia, Vietnam, etc.

We provides a range of services for bauxite mining projects, including project development advisory, concept design, feasibility studies, process design, equipment selection and integrated supply, construction and installation, operation and maintenance on site, financing services.

We have a team of experts that are knowledgeable about the latest technologies and best practices in bauxite mining. We are committed to delivering high-quality products and services on time, within budget, and to the highest standards of quality that meet or exceed the specific needs of each client.

Contact TechSolutions

To learn more about our integrated solutions in bauxite mining, please contact us at service@techsolutions.com.cn or call us at +86 21 6890 6101.