How Does Circular Stockyard Stacker Relcaimer Work?

Overview

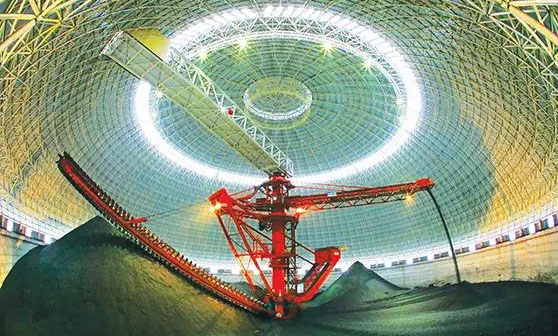

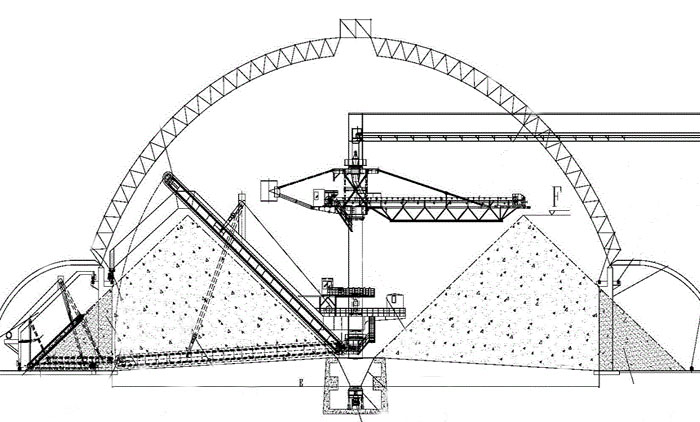

Circular stockyard stacker relcaimers are used for bulk material handling applications, which has compact structure, can stack and reclaim bulk material simultaneously. Circular stockyard stacker reclaimer is designed to stack bulk materials transported by trestle belt conveyor system to the circular stockyard or reclaim bulk materials through scraper in the stockyard then put the bulk material into hopper and chute system under the central column.

Main Features of Circular Stockyard System

Circular stockyard stacker relcaimer is environment-friendly, has the characteristics as follows:

- Environment Friendly

- Occupy less land

- Large Storage Capacity

- High Blending and Homogenization Ratio

- Stack and reclaim at the same time

Working Process

Bulk materials are transported to the trestle belt conveyor in the circular stockyard via the transfer station, the trestle belt conveyor passes through the dome roof and is supported at the top of the central column of the circular stockyard stacker reclaimer. The transported materials are stacked into a circular cone shaped stockpile by the circular stockyard stacker, and the circular stockyard scraper reclaimer scrapes the bulk materials into the cone hopper and chute sytem under the central column along the slope of the stockpile, then outputs the bulk materials through the vibrating feeder and the underground belt conveyor.

Circular Stockyard Stacker Reclaimer for Buffer Storage

Circular stockyard stacker reclaimer for buffer storage can stack and reclaim bulk materials in circular stockyard by:

- Stacking process

Stacker is located on the center column, allowing slewing and luffing motion, hence stockpile bulk material in a chevron or cone shaped shell method. The height of stacker above the top of the pile is kept at a minimum distance to reduce dust emission. - Reclaiming process

Reclaimer is a cantilever or semi-portal scraper reclaimer, slewing around the central column of circular stockyard stacker reclaimer. By slewing and scraper chain movements, bulk materials are scraped to the base of stockpile, then falls to the hopper located underneath the center column of circular stockyard stacker reclaimer.

Circular Stockyard Stacker Reclaimer for Blending and Homogenisation

Circular stockyard stacker reclaimer for blending and homogenization can blending and homogenizing bulk materials in circular stockyard by:

- Stacking process

Stacker is located on the center column, allowing slewing and luffing motion, hence stockpile bulk material in a chevron or cone shaped shell method. The height of stacker above the top of the pile is kept at a minimum distance to reduce dust emission. - Reclaiming process

Reclaimer is a bridge scraper or bucket wheel reclaimer, slewing around the central column of circular stockyard stacker reclaimer. By sweeping movements of an travelling harrow of reclaimer, bulk materials slide to the base of stockpile, then reclaimed by scraper blades or bucket wheel from the face of stockpile.

What TechSolutions Offer for Circular Stockyard System

TechSolutions is a company that specializes in providing engineering design, procurement, construction (EPC) and operation services for circular stockyard system and circular stockyard stacker reclaimer projects, we has years of experience in the circular stockyard system projects and has completed several circular stockyard projects in China, South Asia, Southeast Asia, etc.

We provides a range of services for circular stockyard projects, including circular stockyard project development advisory, concept design, feasibility studies, process design, equipment selection and integrated supply, construction and installation, operation and maintenance on site.

We have a team of experts that are knowledgeable about the latest technologies and best practices in circular stockyard storage. We are committed to delivering high-quality products and services on time, within budget, and to the highest standards of quality that meet or exceed the specific needs of each client.

Contact TechSolutions

To learn more about our integrated solutions in circular stockyard, please contact us at service@techsolutions.com.cn or call us at +86 21 6890 6101.