Do You Have Bridge Bucket Wheel Reclaimer Project We Can Help With?

Bridge Bucket Wheel Reclaimer – More Efficient Blending Reclaimer

What is a Bridge Bucket Wheel Reclaimer?

Bridge blending bucket wheel reclaimer is a type of bucket wheel reclaimer, which is mainly used in secondary material yards and is suitable for reclaiming blended ore and other bulk materials with particle size of 0 ~ 30 mm. Bridge bucket wheel reclaimer can be used in homogenized raw material plants in steel plants, building materials plants, non-ferrous metals plants, chemicals, thermal power plants and other plants.

The bridge blending bucket wheel reclaimer operates at the end of the material pile, and the piled bulk materials are evenly reclaimed through the movement of the bucket wheel mechanism, rake and long travelling mechanism, and the reclaimed bulk materials is stable in composition.

How does Bridge Blending Bucket Wheel Reclaimer Work?

The bucket wheel mechanism of the bridge bucket wheel blending reclaimer is driven by motor, gearbox, and sprocket to rotate. The bucket on the bucket wheel cuts the bulk materials from the pile in turn and lifts them upward. When the bucket rises to about 150°, the bucket leaves the fixed arc baffle. Since the bucket is a flat structure, the materials in the bucket is discharged onto the belt conveyor through the chute due to its own weight and inertia, and then is sent to the belt conveyor in the stockyard. The bucket keeps rotating, and the material on the belt is also continuous. At the same time, the trolley supporting the bucket wheel also reciprocates left and right on the bridge frame, so that the material cut by the bucket is further mixed. When the trolley moves to any end point at both ends of the bridge frame, the PLC program controls the trolley to move forward a distance (the distance can be adjusted as needed) to make the bucket cut into the pile, the trolley moves in the opposite direction, and the trolley continues to move to the other end. The trolley moves forward one step, and the trolley returns, and this cycle continues to occur to continuously reclaim materials.

Our Solutions for Bridge Bucket Wheel Reclaimer

Overview

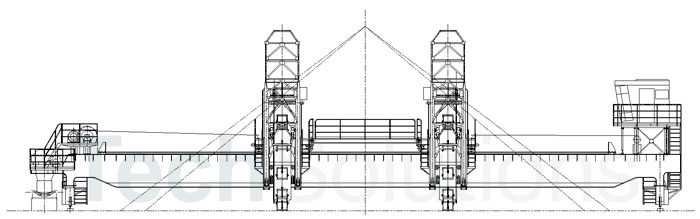

TechSolutions designed bridge bucket wheel reclaimer is used for reclaiming large volumes bulk materials from stockpiles where the efficient blending of material and homogenization is a primary requirement. Bridge bucket wheel reclaimer is typically used at mines, ports, steel plants with rail span up to 65 meters, and capacities of up to 12,500 tons per hour. Rakes are used to direct material flow to the base of stockpile, where then reclaimed by buckets and discharged onto a cross conveyor.

Types

According to the difference in the reclaiming mechanism quantity (bucket wheel mechanism), the bridge bucket wheel reclaimer designed by TechSolutions can be divided into two types:

- Single bucket wheel bridge reclaimer

- Double bucket wheel bridge reclaimer

Main Components of Bridge Bucket Wheel Reclaimer

TechSolutions bridge bucket wheel reclaimer equipment consists of bucket wheel mechanism, harrow device, bucket wheel trolley traversing mechanism, bridge steel structure, trolley traveling mechanism, belt conveyor, cabin, electrical room, electrical control system, monitoring and alarm system, power supply, and lighting, etc.

Main Features

TechSolution bridge-type bucket wheel reclaimer have several features that make them efficient and effective in handling bulk materials. Here are some key features:

- Robust design and modularization construction

- High efficiency reclaiming

- Bi-directional reclaiming

- Optional fully automatic unmanned operation mode

Client Benefits

TechSolutions bridge bucket wheel reclaimer offer numerous benefits to clients across various industries. Here are the key advantages:

- High efficiency and throughput

- Efficient blending of bulk materials

- High degree of mixing and homogenization

- Cost Savings due to minimum working parts and low maintenance

- Reliability and durability

Applications

Bridge bucket wheel blending reclaimers are widely used in various industries for the efficient reclaiming and blending of bulk materials, especially those applications that require high capacity and blending homogenization, such as:

- Raw material stockyards of steel plants

- Building materials / Cement plants

- Non-ferrous metals refinery / smelting plants

- Chemical plants

- Coal-fired power generation plants

- Bulk materials ports and terminals

- Sulphur, phosphate or fertilizer plants / terminals

- Pulp and paper making plants

- Other facilities where efficient reclaiming and blending of raw materials are required

How can we help you?

If you would like to know more about the use of bridge-type bucket wheel blending reclaimer for the stockyard in your industry, how they work, or which solution is best for your business, why not get in touch with our dedicated and knowledgeable team at TechSolutions? With nearly 30 years of experience and some of the best engineers in the industry, you can trust us to provide you and your business with the best solutions, no matter what they may be. So, what are you waiting for? Just chat with our customer care centre:

Tel: +86 21 6890 6101

E-mail: service@techsolutions.com.cn

Alternatively, you can contact our sales team using contact form.

Technical Data

MATERIALS

Bulk materials such as iron ore, coal, bauxite, limestone, etc., especially semi-hard to hard bulk materials

RECLAIMING CAPACITY

up to 12,500 t/h

RAIL GAUGE / SPAN

20 – 65 m

BUCKET WHEEL DIAMETER

5 – 12 m

BELT WIDTH

600 – 2400 mm

Note: Above data can be adapted and may vary according to client’s requirement.

You need spare parts?

QUESTIONS / ORDERS

Phone: +86 21 6890 6101

Email: service@techsolutions.com.cn