Do You Have Drum Reclaimer Project We Can Help With?

Drum Reclaimer – Higher homogenization and blending combined with low maintenance costs

What is a Drum Reclaimer?

Drum reclaimer, also known as a barrel reclaimer, is a specialized reclaiming machine used for bulk material homogenizing and blending, especially in industries such as coal-fired power generation and steelmaking for iron ore and/or coal processing. It plays an important role in efficiently reclaiming bulk materials from stockpiles and blending bulk materials in stockyards.

How does Bridge Blending Bucket Wheel Reclaimer Work?

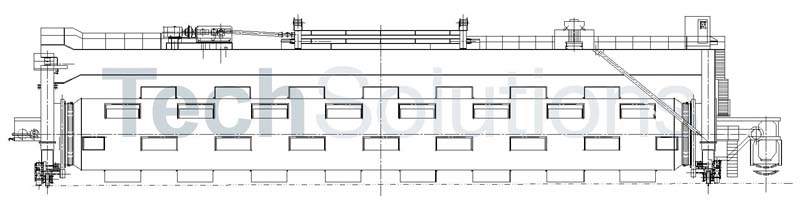

Drum reclaimer consists of a large diameter drum rotating on a horizontal beam and movable material rake, long travelling mechanism, etc. The drum is equipped with a series of buckets or blades mounted on its circumference, with multiple buckets arranged in parallel.

As the long travelling mechanism moves slowly and the drum rotates, these buckets continuously remove thin layers of materials from the cross-section of the stockpile as they rotate, and the buckets or blades reclaim the materials from the stockpile and lift it to a certain height and discharge it onto the belt conveyor inside the drum. The materials are then discharged onto a conveying system or directly to a processing plant for further processing or transportation.

Drum reclaimer is equipped with rakes that are equipped with harrow bars, depending on the particle size of the material to be recycled, and keep the material on the slope of the pile continuously flowing across the width, directly into the reclaiming buckets.

Drum reclaimers continuously reclaim materials from the entire cross-section of the stockpiles, thereby achieving the greatest possible homogenization and blending of material properties and particle size distribution in the final mixture.

Our Solutions for Drum Blending Reclaimer

Overview

TechSolutions have ability to engineering design, modularization fabrication, pre-assembly and pre-commissioning, installation, commissioning and turnkey supply of high capacity, high performance and highly reliable blending drum reclaimers.

TechSolutions designed drum reclaimer is used for reclaiming large volumes bulk materials from stockpiles where high homogenization is an important requirement. Drum reclaimer is typically equipped with rotating drum fitted with reclaiming buckets, materials are fed by harrow in front of drum. The rail span of drum reclaimer is up to 58 meters, and capacities of up to 6,000 tons per hour. Harrow is used to direct material flow to the base of stockpile, where then reclaimed by buckets and discharged onto a cross conveyor.

Types

According to whether it can operate in two working directions for blending and reclaiming, the drum reclaimers can be divided into single working direction drum reclaimers and two working directions drum reclaimers.

- Uni-directional drum reclaimers

Single directional reclaiming, machines have one rake at reclaiming side - Bi-directional drum reclaimers

Two directional reclaiming, machines have two rakes, one on each side

Main Components of Drum Reclaimer

The drum type blending reclaimer is composed of long traveling mechanism, bridge beam steel structure, drum reclaiming mechanism, belt conveyor and beam in drum, rake / harrow mechanism, rake / harrow trolley, cable reel / drum, operator cabin, E-house, etc.

Main Features

Due to design improvements, TechSolutions’ drum reclaimers have features such as reduced wear, lower weight and power consumption, while achieving the optimum homogenization, blending and reclaiming process.

- Excellent homogenization and blending effects

– Simultaneous reclaiming of materials from the entire cross section of the stockpile

– Continuous material flows down to the buckets across the entire stockpile width

– Overlapping discharge of material onto the onto belt conveyor within the drum - Large capacity and steady flow of materials

- Lower weight and power consumption

- Fully automatic unattended operation

- Reduced maintenance

Client Benefits

TechSolutions drum reclaimer offer numerous benefits to clients across various industries. Here are the key advantages:

- Full stockpile face handling ensures high efficiency

- Reliable drum reclaiming technology ensures optimal performance

- Optional smart unattended operation system allow stacker automated operated for cost-effective operation and high performance

- Optional smart condition monitoring and assessment system monitoring & assessing structure stress & vibration and equipment operation data

- Reduced maintenance cost

Applications

Drum reclaimers are designed to handle a wide variety of bulk materials, including iron ores, coal, and other minerals or aggregates. They can handle high volumes of material at a relatively fast rate in a variety of different applications.

- Iron ore homogenizing stockyards of Iron ore plants / Steel mills

- Coal-fired power plants

- Others

How can we help you?

If you would like to know more about the use of drum blending reclaimers for the stockyard in your industry, how they work, or which solution is best for your business, why not get in touch with our dedicated and knowledgeable team at TechSolutions? With nearly 30 years of experience and some of the best engineers in the industry, you can trust us to provide you and your business with the best solutions, no matter what they may be. So, what are you waiting for? Just chat with our customer care centre:

Tel: +86 21 6890 6101

E-mail: service@techsolutions.com.cn

Alternatively, you can contact our sales team using contact form.

Technical Data

MATERIALS

Bulk materials such as iron ore, coal, etc.

RECLAIMING CAPACITY

up to 6,000 t/h

RAIL GAUGE / SPAN

20 – 58 m

DRUM DIAMETER

5 – 8 m

BELT WIDTH

600 – 1800 mm

Note: Above data can be adapted and may vary according to client’s requirement.

You need spare parts?

QUESTIONS / ORDERS

Phone: +86 21 6890 6101

Email: service@techsolutions.com.cn