What is the Advantage of Circular Stockyard Comparing with Longitudinal Stockyard for Bulk Material Handling?

In the material conveying systems of thermal power plants, ports and terminals, mining and metal, cement and building materials, chemical and other industries, bulk material storage and handling is an important step, whose main function is to buffer and adjust the imbalance of working system and capacity between production and material outward transportation, and to ensure the normal outward transportation of materials when production is stopped due to climate, maintenance and failure of production equipment, which is the key to the normal operation of the whole system.

What is the Advantage of Circular Stockyard Comparing with Longitudinal Stockyard for Bulk Material Handling?

Storage Types of Bulk Materials

Bulk material are stored in different methods in various industries, depends on the convenience for bulk material handling and conveying when all these bulk material required for processing. Generally, the storage types mainly include silos, circular stockyard and longitudinal stockyard:

Longitudinal stockyard system is used widely in thermal power plants, ports and terminals, mining and metal, cement and building materials, chemical and other industries.

Advantages of Circular Stockyard System Comparing with Conventional Longitudinal Stockyard System

Comparing with the conventional longitudinal stockyard and equipment, the advantages of circular stockyard are as follows:

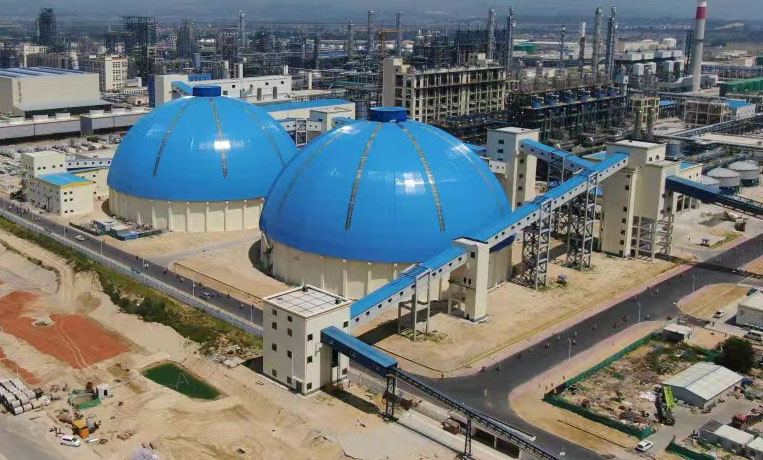

1. Outstanding environmentally friendly performance

The circular stockyard has outstanding environmental protection performance. With the needs of China’s modernization and people’s increasing awareness and requirements for environmental protection, this kind of advanced fully enclosed circular material yard and its equipment have been widely valued by people and played an important role in environmental protection in the surrounding areas. It has solved the pollution problem of the storage yard to its surrounding environment.

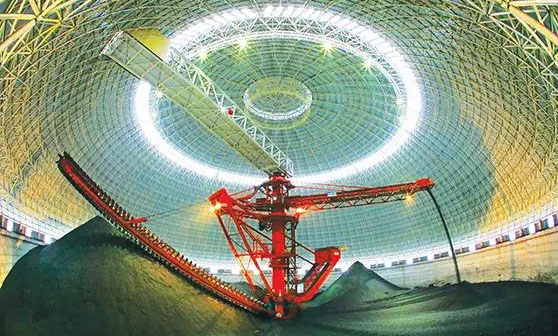

2. Fully automatic program control continuous operation

Circular stockyard has advanced technology and high program control level. The whole yard is controlled by PLC programming, organically by the nearest control and remotely by the centralized control room. There are cameras around the yard and monitors in the program-controlled room, which is convenient for operators to monitor and operate the yard in the program-controlled room. The high automation operation of the circular stockyard greatly improves the production efficiency and reliability of the whole coal conveying system and the automation level of the large stockyard.

3. Occupy a small area and saves construction land

The circular stockyard has a small floor area and a high utilization rate. The earthwork volume is much lower than that of the long stockyard, especially for the projects that need to open mountains and fill the sea, and the advantages of civil engineering are more obvious.

4. Avoid the influence of bad weather on the safe operation of the stockyard system

Avoid the influence of bad weather on the safe operation of coal storage plant. Generally, the wind and rain in the stockyard have a great impact on the bulk materials, which further affects the material conveying system, while the circular stockyard with totally enclosed structure has a great protective effect on the materials, totally free from bad weather.

TechSolutions Offer Customized Circular Stockyard System and Longitudinal Stockyard System

TechSolutions can provide customized circular stockyard system and longitudinal stockyard system with better cost performance according to clients’ actual requirements.

Our offered circular stockyard system and longitudinal stockyard system or related equipment can be used for storaging & blending various bulk materials such as coal, coke, ore, ore sand, petroleum coke, cement, fodder, fertilizer, woodchips, sulfur, grain and salt, etc.

How can we help you?

If you would like to know more about the use of circular stockyard system and longitudinal stockyard system in your industry, how they work, or which solution is best for your business, why not get in touch with our dedicated and knowledgeable team at TechSolutions? With nearly 30 years of experience and some of the best engineers in the industry, you can trust us to provide you and your business with the best solutions, no matter what they may be. So, what are you waiting for? Contact us to transform your business today.

If you need support, just chat with our customer care centre:

Tel: +86 21 6890 6101

E-mail: service@techsolutions.com.cn

Alternatively, you can contact our sales team using contact form.

Interested in the quality services provided by TechSolutions? Check out our brochure and detail performance list circular stockyard system and longitudinal stockyard system for more information.